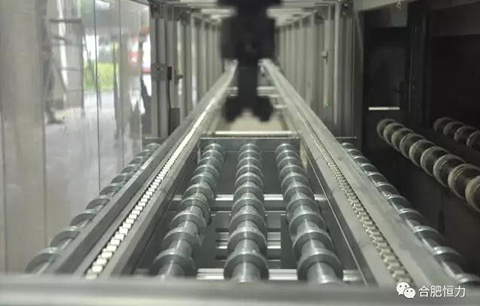

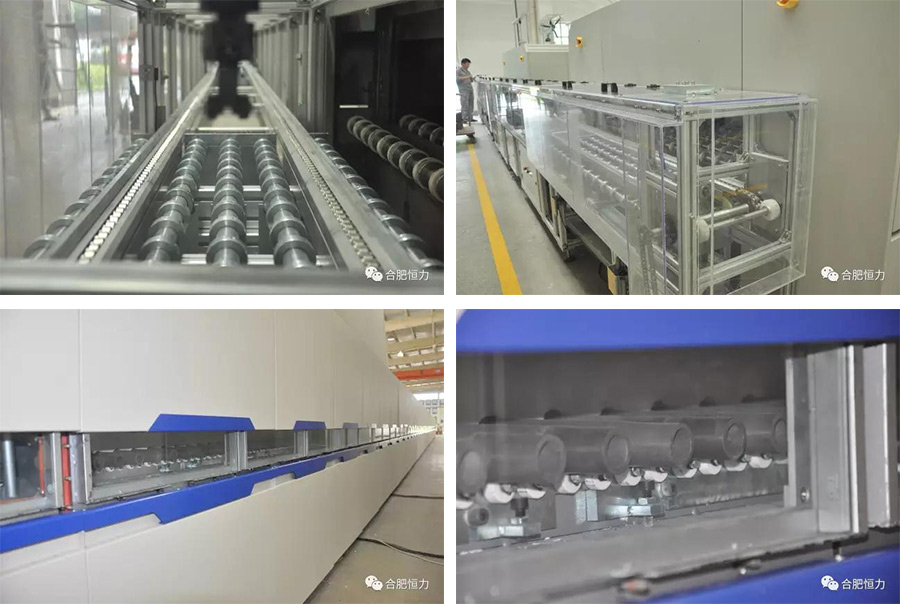

Air roller hearth furnace

Heat treatment process for lithium ion materials such as ordinary three yuan

1、Index parameter

Rated temperature: 700-1050 degrees centigrade

Maximum temperature: 1200 degrees centigrade

Sintering atmosphere: air

Heating element: heating wire / silicon carbide rod

Heating element layout: up and down heating

Effective height: 150mm/200mm/250mm/300mm

The total height of the equipment: < 2100mm

2、Progressiveness

1, accurate exhaust structure and control to effectively ensure furnace pressure.

2. Special heating zone setting, multi segment temperature control accuracy is higher, achieve precise temperature control of + 1 degrees centigrade.

3. Special furnace design, area production increased by 1.5-2 times.

4. Alumina hollow ball bricks are used in the furnace to resist strong alkaline corrosion.

5, the driving structure and the roof exhaust structure ensure the realization of the above performance.

6, energy conservation, electricity, atmosphere and other energy saving programs.

(Ps expert's message: about 20% of the heat energy is dissipated by the end of the roller. To this end, the atmosphere roller hearth furnace on both sides of the heating rod sealing cavity and transmission seal cavity, all installed with air inlet nozzle, direct air blowing cooling roll rod ends, and the air of the seal cavity pressure from the installation hole pressure into the furnace, on the one hand the atmosphere is preheated, on the other hand, due to positive pressure, effectively prevent the rod hole heat dissipation! At the bottom of the heating section and the constant temperature section, a number of small holes are opened in the bottom of the insulation layer. The atmosphere is divided into the middle and right of the furnace at the bottom of the furnace, and the air volume is adjustable in the direction of the width of the 3 way. )

3、Detail display

- Prev:Nitrogen roller hearth furnace

- Next:无